Our Business

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

Toys, Model Hobby & Sports

MPPL embarked on a groundbreaking journey into contract toy manufacturing. Four sprawling plants, covering a colossal one million square feet in Bangalore and Hosur, now stand as testament to their ambition.

Key Highlights

Key Highlights

Infrastructure

Built-up Space of 4500 Sqft.

- Pick and Place with 75,000CPH (Components per Hour).

- AOI- Automated Opticalinspection for SMT PCB panels.

- Manual Insertion and Wavesoldering for mass scaleproduction.

Capacity

Annual Capacity

- 2 Million PCBA/ Year in single shift.

- Provision to expand PCBA output based on pre informed demand plan.

New Product Development

In house Design Studio

- Design studio for swift product development and handling changes in Pilot run.

- NPD team to handle running changes and Prototyping.

Quality Management System

Quality Control

- ISO- 9001-2015.

- Quality Checkpoints in all stages of operation.

- Raw materials sourcing from qualified suppliers.

- Identification and traceability system.

Our Portfolio

Our Portfolio

Toys & nerf

RC cars

Fashion dolls

Plush toys

Board games & puzzles

AR & VR

Hobby model kits

Dino’s

Molding

Molding

Toy plants house a staggering 350 injection molding machines, ranging from 30 to 470 tons, as well as Roto Molding and Blow Molding machines. The division also has over 250 manual and 20 automatic spray booths and operate a fully automatic darts manufacturing setup, churning out an astounding 200,000 darts daily.

PCBA

PCBA

The integrated PCBA manufacturing is equipped with Yamaha. Pick and Place with 75,000 components per hour, Automated Optical inspection for SMT PCB panels, Manual Insertion and Wave soldering for mass scale production and testing.

Plush Toys

Plush Toys

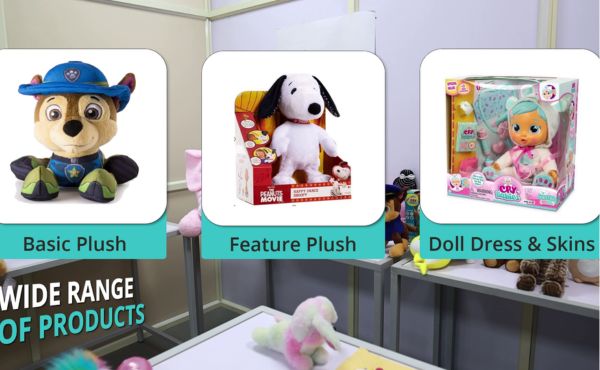

The integration in Plush has helped the Toys division to offer customers wide range of products in basic plush, feature plush and capability to produce dress and skins for Dolls with its own Design studio for swift product development and handling changes in Pilot run and dedicated design team for embroidery and printing design requirements. Additional equipment’s include 90 sewing machines. Embroidery, Hydraulic, Laser, Hot press & Layer cutting machines and UV tunnel and Metal Detector.

Sewing / Cutting

Sewing / Cutting

Additional equipment’s include 90 sewing machines. Embroidery, Hydraulic, Laser, Hot press & Layer cutting machines and UV tunnel and Metal Detector. The Toy division has grown to become “One stop solution” to customers developing expertise in Mechanical Toys, Electronic Toys, Dolls and Plush. The division has developed expertise in Dolls with skills in Roto Molding, Complex decorations using multi station Tampo, Automatic Spray, Digital Ink jet, Hair Rooting and Hair grooming. MPPL manufactures and exports 25 million toys and model kits annually to top international toy brands like Hasbro, Spinmaster, Casdon, MGA, Simba Dickie, Playshifu, IMC and Hornby Hobbies to name a few.

Quality

Quality

Testing Excellence

The Company follows highest quality and safety standards for Toys and Model Hobby Kits. All the materials comply with EN71 standards and are checked both internally and using external certified labs like SGS, TUV & Intertek. The In-house quality lab conduct rigorous checks from Incoming to shipment ensuring quality at every stage.

The company practices the highest ethical and safety business standard and is certified with RBA, ICTI Class A, GSV, CTPAT which are the backbone of the toy industry across the globe. The division is audited and approved by major international retailers like Walmart, Disney, Target, Amazon and direct shipments are made to these retailers in every part of the world.